Saving Adam: Scansite3D helps restore Tullio Lombardo’s Adam Sculpture at the New York Metropolitan Museum of Art

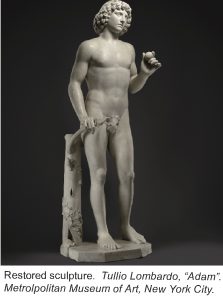

San Rafael, California – October 26, 2015 – Scansite3D (www.scansite.com), the leading innovator in museum quality 3D scanning and virtual reconstructions announced today its role in the restoration of Tullio Lombardo’s Adam, the crowning pride of the Metropolitan Museum of Art’s Venetian Renaissance Sculpture collection. It was October 2002 when the podium supporting the masterpiece buckled and Adam tumbled to the floor. One of the most precious art pieces in antiquity, now reduced to hundreds of fractured pieces, needed help. That’s when the Museum turned to the expertise of Scansite3D. Commissioned in the 1490s, in its original state Adam is life size and 880 pounds of Carrara marble. When Scansite3D arrived on the scene, only 28 major fragments along with over 400 minor pieces and a pile of marble dust were all that remained. It was clear that the task at hand was going to be deliberate and painstaking!

Creating Virtual Adam

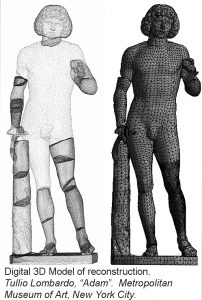

The work that Scansite3D accomplished was the foundation for this 12-year restoration project. After Scansite3D digitized the broken fragments, they embarked on a two year journey to precisely reassemble the pieces into a 3D digital computer model. The challenge was exponentially enhanced because when stone breaks, it expands. Perfectly retrofitting all of the fragments back together required the detailed and exact work for which Scansite3D is known for. Once the 3D model was created, Scansite3D then reversed the digital data so that a CNC mill could create a foam cradle in which to house the fragile fragments.

Creating Virtual Adam

The work that Scansite3D accomplished was the foundation for this 12-year restoration project. After Scansite3D digitized the broken fragments, they embarked on a two year journey to precisely reassemble the pieces into a 3D digital computer model. The challenge was exponentially enhanced because when stone breaks, it expands. Perfectly retrofitting all of the fragments back together required the detailed and exact work for which Scansite3D is known for. Once the 3D model was created, Scansite3D then reversed the digital data so that a CNC mill could create a foam cradle in which to house the fragile fragments.

Creating Virtual Adam

The work that Scansite3D accomplished was the foundation for this 12-year restoration project. After Scansite3D digitized the broken fragments, they embarked on a two year journey to precisely reassemble the pieces into a 3D digital computer model. The challenge was exponentially enhanced because when stone breaks, it expands. Perfectly retrofitting all of the fragments back together required the detailed and exact work for which Scansite3D is known for. Once the 3D model was created, Scansite3D then reversed the digital data so that a CNC mill could create a foam cradle in which to house the fragile fragments.

The next task asked of Scansite3D was even more challenging! The Museum needed a way to accurately get the digital reassembly into finite element (FEA) software to identify structural points for the physical reconstruction. Having pioneered the field of reverse engineering for use with their manufacturing clients, Scansite3D built a suitable 3D engineered CAD file over the scan data and from there, the team was able to use ‘Virtual Adam’ to tell them exactly how to put back together ‘Physical Adam’.

“We’re very proud of our involvement with the Metropolitan Museum and cultural heritage work has long been one of our specialties; but this project

pushed the boundaries in terms of technology and pioneered a new way of thinking about what’s possible in conservation.”

Lisa Federici, CEO of Scansite3D

About Scansite3D

With its internationally acclaimed studio in the San Francisco Bay Area, Scansite3D is a full-service 3D metrology, 3D content, inspection and reverse engineering company. With the expertise and attention to detail necessary to cater to world-class museums, Scansite3D provides state-of-the-art services with meticulous detail every time.

CONTACT: Media relations, pr@scansite.com, (415) 488-9500